Technology

Patents

The present invention is directed to a system and method for measuring water content or water cut in fluids and in a petroleum/gas-water mixture. Specifically, the invention relates to a system and method to be used in oil production facilities where fluids extracted from the subsurface exhibit characteristics of hydrocarbon-water mixtures with variable salinity levels.

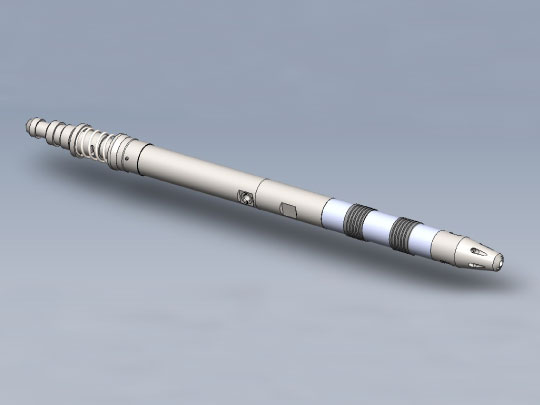

The present invention relates to a system for monitoring producing and/or injecting wells in enhanced oil recovery processes, wherein the system enables continuous monitoring of downhole pressure and temperature, with the information being transmitted in real-time via telemetry and/or stored in memory for long-term logging.

Learn More

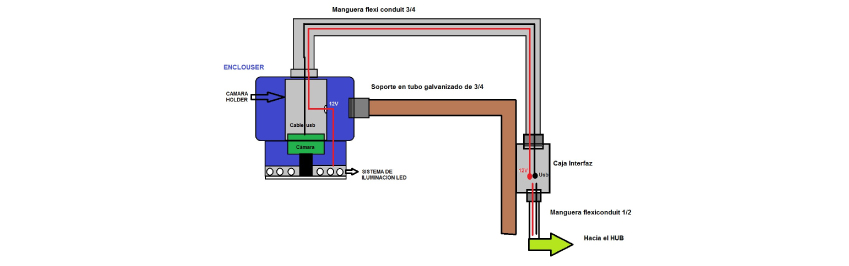

Learn MoreThis invention is related to the technology for measuring water quality through multiple parameters that are required to identify that aqueous solutions from hydrocarbon discharges, treatment plants and wastewater, among others, meet the requirements required for prevent contamination and maintain strict control in other processes where these water sources are used. For this purpose, not only are the parameters measured on site through sensors specially manufactured and conditioned for these environments, but the information is processed and transmitted in real time for local and remote storage and management through the Internet, allowing the control of these online processes. Likewise, the sensors and the respective electronics are installed in an encapsulation made of special very low friction material type R2C(OR’)2 that prevents the adhesion of hydrocarbons and other substances that can affect the reading and allows the sensors and electronics to be submerged. up to at least 10 meters deep ensuring adequate measurement of water quality in multiple conditions.

This invention describes a sensor for the measurement of suspended solids in water, based on transmittance and back-dispersion techniques, designed for the measurement of suspended solids in waters with the presence of hydrocarbons and mixtures of water and other fluids. The sensor comprises sources and receivers of electromagnetic radiation, a mechanical system or polymer encapsulation with a low coefficient of friction, an electronic processing and control system that delivers a voltage output proportional to the concentration of solids suspended in water and a system of electrical power of the system based on rechargeable batteries and energy sources such as solar panels, wind generators or industrial electrical networks.

Articles

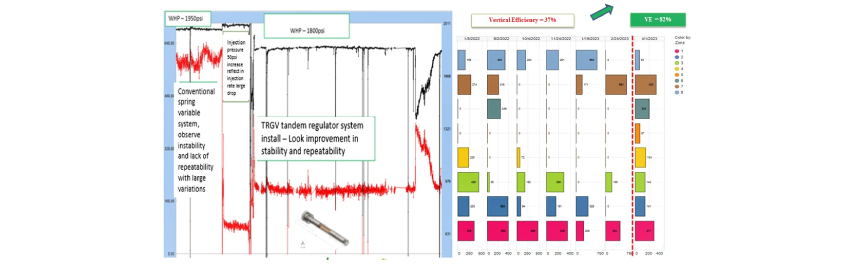

Historical cases of use of valves with sensors for optimization of injection and production in static and dynamic conditions.

Direct monitoring of water and polymer injection conditions in multiple and laminar reservoirs in secondary recovery in oil reservoirs is very important to optimize and improve injection and production, the development and use of technology to measure and monitor conditions is necessary. real static and dynamic reservoir and injection.

Monitoring pressure and reservoir parameters during water injection in secondary recovery – reservoir model and selective injection system.

Reservoir model subjected to water injection identifying front in the nearby area with pressure increase and original remote area with initial parameters – paper spe 7003.

selective injection system used in Colombia

The importance of real time monitoring and early alert systems to optimize efficiency, costs and production, Also use in early enviromental early system.

Succesful Development Of The Smart Water Cut Monitoring System And A System To Monitor Reservoir Parameters In Real Time Between Ecopetrol And Jpt.

Pre and Post Characterization of New Enhanced Oil Recovery Technologies based on Transducers and Tools developed in Colombia.

Characterization And Identification Of Fluids Using Electrical Techniques For Petrochemical Applications.

Design and Implementation of a High Sensitivity Differential Pressure Sensor for Petrophysical Applications.

Integration of hardware

and software to optimize

the real time monitoring

for digital oil fields.

Multiparameter Real-Time Water Quality Monitor including measurement of oil suspended in water for control of discharge and injection in plants crude oil treatment.

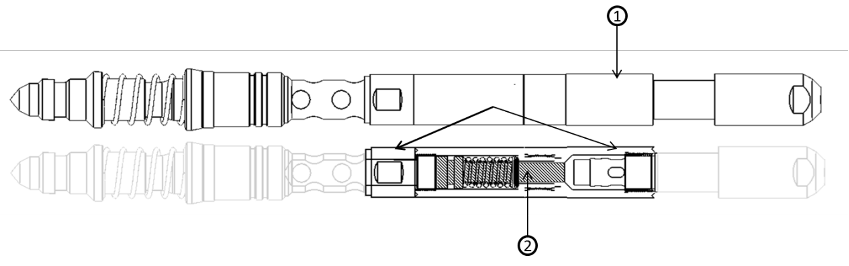

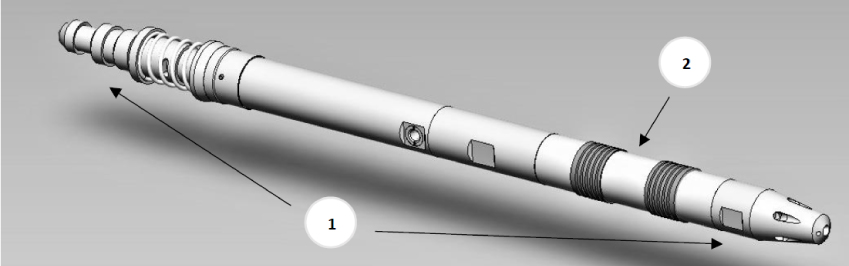

Optimization of water and polymer injection control valves for improving secondary recovery in pipes with mandrels.

Monitoring of production and reservoir parameters downhole for fields mature using multiple PLT tools connected in tandem and in time real for producing wells with artificial lift.

Real Time Monitor of Multiparameter Water Quality including measurement of

suspended oil in water for control of discharge and injection in crude oil treatment plants.

Water Quality Monitoring and Oil Suspended in Water Detection In Real Time : A Case Study for the Technology Development and Applications to Support Water Processing and Management in Mature Heavy Oil Fields.

Case Histories of Water and Polymer Injection Regulator Valves with Fixed Regulators

in Selective Injection System to Improve Secondary Recovery in mature fields.

Water Quality Monitoring and Oil Suspended in Water Detection In Real Time : A Case Study for the Technology Development and Applications to Support Water Processing and Management in Mature Heavy Oil Fields.

Development and Application of Water and Polymer Injection Control Valves Including Memory Recording of Flow and Pressure to Improve Secondary Recovery Surface and Downhole for Completion Using Side Pocket Mandrels: Case Histories.

“Development And Application Of Water And Polymer Injection

Control Valves Including Memory Recording Of Flow And Pressure To Improve Secondary Recovery Surface And Downhole For Completion Using Side Pocket Mandrels: Case Histories”.

Oil In Water Quality Monitoring In Real Time: Applications

For Produced Water: Disposal And Re-injection Case Studies.

Oil In Water Quality Monitoring In Real Time: Applications For Produced Water: Disposal And Re-injection Case

Studies.

Oil In Water Quality Monitoring In Real Time: Applications For Produced Water: Disposal And Re-injection Case Studies

The present paper introduces an integrated equipment system developed and patented jointly with Ecopetrol to monitor in real time water quality parameters for produced water from mature fields. This paper includes equipment details starting from electronics to the description of a special package developed to detect suspended oil in water. The field implementation meant a new and more cost-effective manner to not only monitor water quality but also to improve operation sequences in treatment plants. Monitoring process is necessary to control the quality from production and processing water plants consideringthe importance of keeping all the parameters within the limits established by regulations or recommendations,including the volume of suspended oil in water.